What Is Wall Covering and What Makes It Special?

Wall covering involves applying a fabric — comparable to curtain or upholstery fabric — directly onto the wall.

Unlike regular wallpaper, which is usually stiffer and glued in place, wall covering uses a woven material that must be stretched. It cannot be glued.

Historically, wall covering has been a symbol of luxury and status. In earlier times — during the Middle Ages, the Renaissance, and later in French châteaux and Dutch manor houses — walls were covered with fabrics, leather, or wood: the summum of luxury. It served as a status symbol long before paintings became popular in the 17th and 18th centuries.

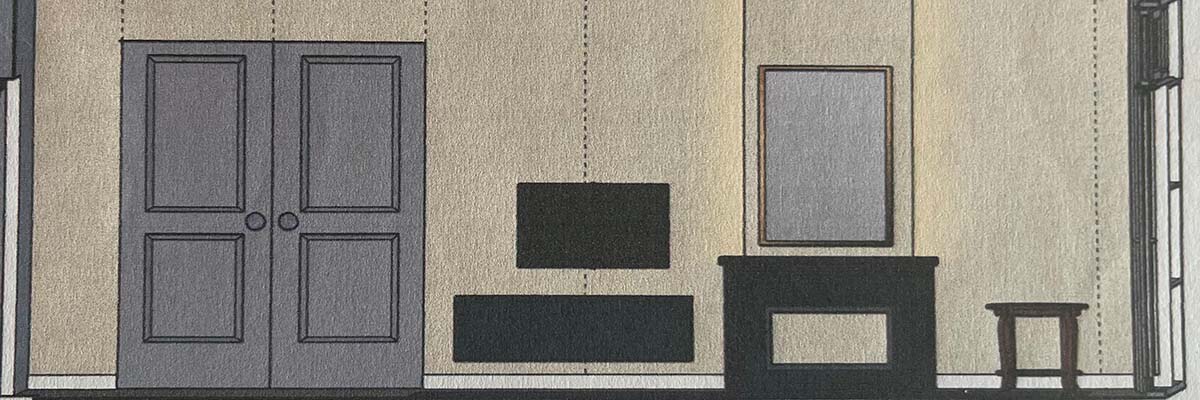

Even today, wall covering creates a richer appearance than traditional wallpaper. The chosen fabric in this project was calm yet luxurious, with a hint of texture, matching perfectly with the classic sense of luxury the clients wanted to achieve.

Wall covering offers an essential functional advantage: acoustic damping. Because it is a woven fabric, its acoustic properties are naturally much greater than those of most types of wallpaper. To effectively address acoustic issues, it’s crucial that a large surface area is treated.

In addition, the solution is very durable. Even if the residents ever tire of the look, wall covering tends to stay beautiful for a very long time. It is also resilient: you can bump into it without leaving marks because the fabric gives slightly.

A practical technical benefit is the flexibility for wiring. The space created behind the stretched fabric can be used to run new cables (for example for lighting) without needing to chase into the wall.

Craftsmanship and the Specialist Process

Installing wall covering is a specialist trade. It’s estimated that there are only about five specialists in the Netherlands capable of achieving this level of craftsmanship.

The process requires extremely precise and detailed preparation:

Phase 1: Preparation of the Substructure

- Removing Old Materials: For the best result, the old wallpaper in the room was completely removed to avoid building over existing materials.

- Installing Battens: Battens were fixed along the contours of the walls (and sometimes ceilings).

- Creating an Air Layer: A small air gap was left between the wall and the battens. This air layer provides both insulation and additional acoustic performance.

- Applying Molton: A layer of molton (thick felt) was then stretched over the battens. The molton serves two purposes: enhancing the acoustic properties and ensuring a more beautiful, fabric-like finish — comparable to a lined curtain.

Phase 2: The Fabric Work in the Atelier

- Fabric Selection and Restrictions: Technically, not all upholstery or curtain fabrics are suitable. The fabric’s reaction to humidity must be considered — a fabric that “works” or shifts can cause rippling over time.

- Preliminary Cutting (Sewing): Because the room in this villa was higher than 2.80 metres, the fabric had to be joined in panels.

- Precision Stitching: The entire wall was measured to determine exactly where each panel would join.

- Blind Stitching: The panels were blind-stitched together with millimetre precision in the atelier. Seams were reinforced on all sides — top, bottom, and edges. The finished fabric package was then carefully transported to the site.

Phase 3: Mounting and Detailing on Site

Cutting Out Details: Elements such as open corners, sockets, and switches were precisely cut out from the stretched fabric.

Stretching: The fabric was stretched tightly around — bottom, top, and sides — using the battens to keep it in tension.

Finishing: Finishing and tensioning were done on site. The wall covering always follows the contours of the wall, even on slanted planes.

The end result was a room that, thanks to its rich appearance and the careful execution of this specialised craft, achieved the desired classic sense of luxury along with perfect acoustic conditions.